BUYING A HELICOPTER

How to predict your helicopter’s maintenance operating costs

Maintenance operating costs are arguably some of the more complicated costs to estimate when predicting the overall cost of helicopter ownership.

By: Jen BoyerPosted on: December 4, 2023

Maintenance operating costs are arguably some of the more complicated costs to estimate when predicting the overall cost of helicopter ownership. While not as cut and dry as monthly hangar rent or loan payments, they can be narrowed down to a fairly accurate range to help a potential new helicopter buyer make a purchase decision.

Kenny Morrow is the chief operating officer for Metro Aviation, a full-service completion center and emergency medical services (EMS) aircraft operator. For Morrow, an accurate estimate of maintenance operating costs is vital in bidding for EMS contracts and helping customers acquire helicopters that will operate within their budgets. Throughout his years of experience in sourcing aircraft for customers and Metro, he’s developed a system to predict operating costs on an aircraft regardless of its age or manufacturer.

“If you want to get technical, there are two parts to these operating costs,” Morrow explained. “The first is direct costs like pilot salaries and benefits, landing fees, and fuel. The second is maintenance costs.”

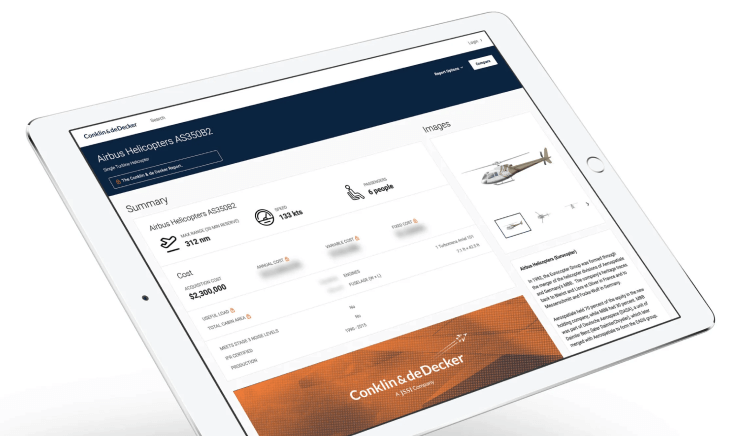

Morrow recommends investing in a resource that can pull together general information on thousands of aircraft operating around the world. When lacking experience in a particular airframe, he uses Conklin & de Decker as a starting point, purchasing aircraft cost reports for $150 each that break down all operating and maintenance costs based on the aircraft’s make and model. Together, these provide an average per-hour maintenance cost and overall operating cost. Morrow believes that this provides a low-end range guide or bracket of what the direct maintenance costs for that airframe should be.

“You really have to study the breakdown of what is included in the hourly cost,” Morrow said. “I’ve found Conklin & de Decker to be fairly accurate as far as a starting point.”

For aircraft manufactured within the past 10 years, Morrow also recommends contacting the aircraft manufacturer to get quotes on their power-by-the-hour (PBH) programs that cover scheduled and unscheduled maintenance for certain defined components. These programs allow an aircraft owner to pay per-hour costs to the manufacturer to cover specific components of the aircraft that could have unforeseen maintenance events. Generally, the PBH programs offered by the manufacturers can be provided with or without engine coverage. It is helpful to obtain pricing for both options.

As a third step, he suggests contacting the engine manufacturer to request a power-by-the-hour quote for the aircraft’s engine. Morrow cautions potential buyers to be sure to get a quote for both hours and cycles. Increased cycles (number of times the engine is started and stopped) can increase the cost, as some engine components are cycle limited rather than hour limited. This allows buyers to compare what the aircraft manufacturer is charging for the engine PBH to what the engine manufacturer quotes.

“PBH programs are like insurance for those really expensive costs, especially related to dynamic components,” Morrow said. “The rates they quote per hour for your aircraft are at the higher end of what you would expect to experience as actual maintenance costs. By taking the Conklin & de Decker report as a low-end bracket and the manufacturers’ PBH quotes as a high-end bracket, you should be in the ballpark of estimating your direct maintenance operating costs, within 20% or so.”

Metro Aviation Photo

For reference, Conklin & de Decker will break down estimated variable and fixed costs to include fuel, lubricants, pilot salaries, insurance, training, hangar fees, and other potential costs, in addition to labor and a general per-hour line item for maintenance, as well as part repair, replacement, and overhaul. Of note, Conklin & de Decker commonly estimates an hour of labor per hour flown in a single-engine turbine helicopter and employs an average hourly labor cost. Morrow said labor costs are close to $150 an hour today on average. That’s a starting point as the maintenance facility that the owner chooses to use may charge differently.

PBH programs may or may not include labor and only cover specific items, so Morrow cautions people who are comparing all these costs to read the fine print to ensure they account for all costs.

Of course, this strategy is simply a starting point. Once a potential buyer has gathered this information from all parties, numbers can be fine-tuned based on the aircraft’s age and the owner’s intended use.

For instance, a helicopter engine with a 4,000-hour time before overhaul (TBO) may already have 1,400 hours when the new owner purchases it. If it costs $400,000 to overhaul the engine, the new owner would need to account for making that payment in 2,600 hours. The engine overhaul reserve would be $154 an hour in that case. Had the aircraft been new or had a freshly overhauled engine, that same allowance would be $100 an hour. Of course, this does not take into account early removal for interim repair or the engine not making it to TBO.

This same methodology would need to be applied for all other life-limited components. The new owner can reverse engineer the maintenance allowances by working with a maintenance facility familiar with the aircraft make and model to get a clearer picture of maintenance for that particular aircraft.

Finally, nothing beats experience. Morrow recommends building your spreadsheet as best as possible with all the information that you can gather and then talk with as many people and operators as possible who are familiar with operating and maintaining the aircraft make and model. The aircraft broker and seller should be willing to provide information related to historical expenditures that will also help to build that spreadsheet. A good best practice, he said, is to keep digging until you start hearing the same information from multiple sources.

Sikorsky S76C++

Make an offer

Year: 2008

MD Helicopters MD500D

Contact seller for price

Year: 1979

MD Helicopters 369E

USD $ 244,000

Year: 2008

Airbus AS350B3+

Contact seller for price

Year: 2010

Robinson R66 Turbine

USD $ 785,000

Year: 2015

Sikorsky S76C+

Contact seller for price

Year: 1999

Airbus EC120B

Make an offer

Year: 2002

Airbus SA341

USD $ 695,000

Year: 1976

Robinson R22 Beta

USD $ 163,000

Year: 1988

Airbus H125

Contact seller for price

Year: 2023